A customer approached us with an idea to modify his Honda CB550 four to a similar spec to one he saw on Google pictures but with some of his own personal ideas embedded into the finished creation .I was only too pleased to undertake the task as it was a step away from standard restoration work on vintage, veteran and classic machinery.

All bits for the bike were to be off the shelf parts that are commonly available. Hmmm! I bet I’m going to have a lot of input on how to make the off shelf parts marry up together with what’s going to be left of the original machine. It appears that the Americans like these bikes on the basis of some type of customization, IE; Bobbers, chop or desert sledge to name a few, I suppose it was the cast amount of sales from Japan to the USA of this particular model. So, many years later a cast amount of spares, new and used are still obtainable for engine and chassis restorations.

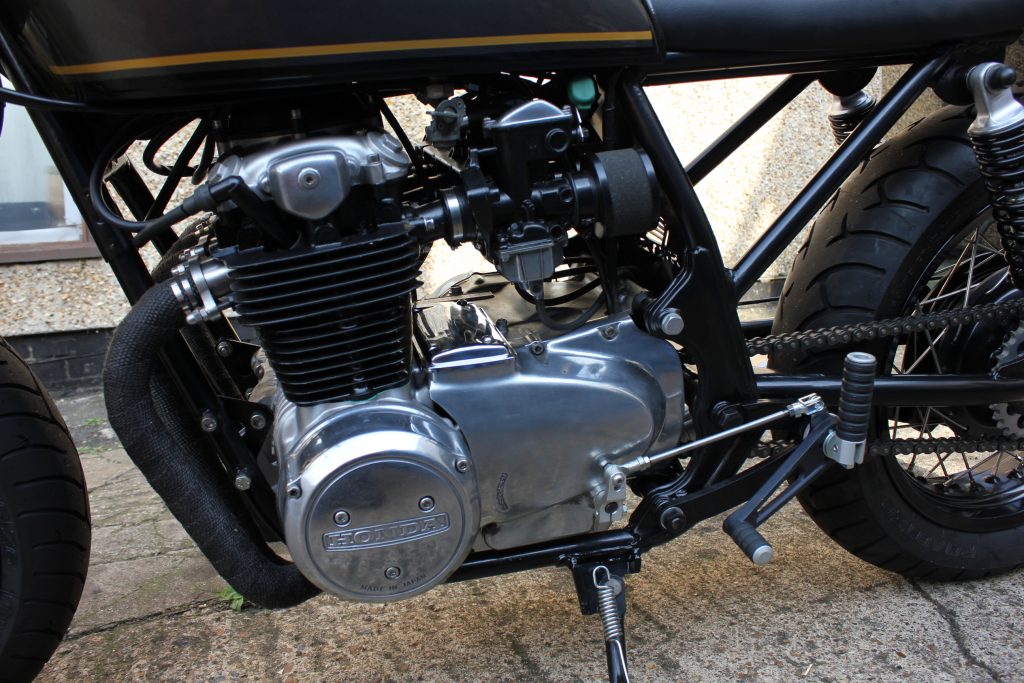

The customer wanted the engine to be a standard, as new restoration except for paintwork on the external casings and the carb bodies. The customer who I will call “Mat from now on was told to go shopping for parts such as forks, wheels, seat, exhaust, brakes, lights and any other gadgetry that he wanted to be fitted and I will somehow get it all to work together with the help of our vast array of machinery in the workshop. The engine was the first part to be tackled by me, and my son was told to start initial modifications to the frame.

All pictures are of the finished bike.

The engine looked ghastly and the odometer reading of 17,000 miles was very suspect until I noticed that none of the engine screws or bolts had been tampered with. The engine came apart easily and showed minimal ware to all components but I thought it prudent to renew the piston rings. All of the engine cases were vapour blasted as well as the barrels and then we sprayed it with heat and ethanol proof paint “You will find a chart on heat proof paints and there properties on one of my older blogs”. Parts started to roll in from people who mat bought stuff either from ebay or suppliers of custom parts such as Moto gadget.

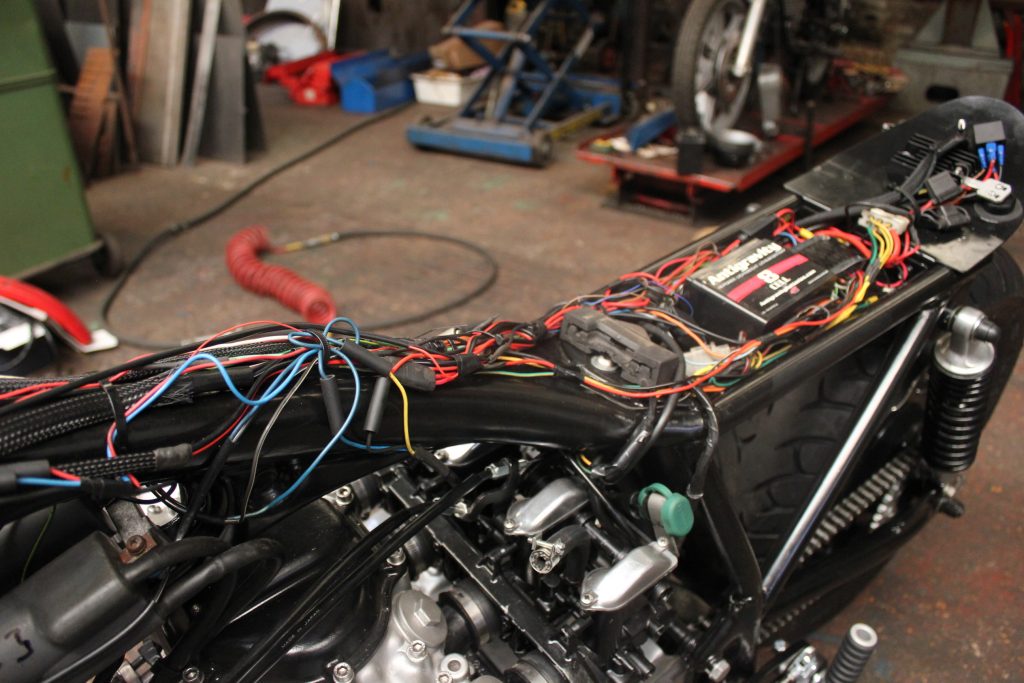

Mat told us how he wanted the frame tail end to look like and all of the electrical if possible were to be hidden under the seat unit. The seat was offered up to the bike and a few nips and tucks to the frame and a tray under the seat that could be removed if needed was all completed. I’m not going to go into all the template and pattern making to produce what has been achieved because it would be patently boring. The seat was a very low profile as was the tray that fitted beneath it. After the frame modifications has been completed I had to cut a sheet of metal for fitting in between the seat down tubes and laser cut the Honda motto in the centre.

The forks provided are upside down forks and came with the top and bottom yolks. Little work was done to make them fit. The rims came in from central wheels, they are black anodised on aluminium and they show up marks such as scratches very easily as the anodising is only microns thick. I worked out the spoke lengths for both front and rear wheels and after they arrived from Hagon Wheels I rebuilt them in an evening. As you will see the rims are far from standard. The rear rim with tyre fitted and set up squarely in the swing arm only misses the chain by a couple of millimetres. Hagons shocks were fitted and the bottom mounts met with the standard CB550 hub.

The frame was a simple modification . The wheel builds were relatively easy. The electrical components tray underneath the seat was very awkward. The forks and headstock fitted beautifully with a couple of bearing modifications. Now comes the electrics that were a pain in the arse. The front and rear indicators and the electrical management system are supplied by Moto gadget. I’m not an electrics man but I’m sure that the Moto gadget stuff doubled the amount of wires that would have been needed on a standard wiring loom. The heart of the electrics is a hand operated control box that has loads of operational information regarding safety and absolution from all responsibility and a host of warranty clauses. My question is why the complications? If you want something classic, why have all the guff that does not fit the era? I would prefer an independent indicator relay. Independent starter relay and so on. The problem is with the unit if a circuit goes down that part of the unit has to be substituted with something more conversional and repairable. The Moto gadget unit has to be absolutely water proof as a friend of mine has had no end of problems with moisture ingress.

Maybe I’m a traditionalist and like to stick with old shit that I can fix. rather than a wrath of paperwork that comes with the black box exonerating the seller or manufacturer from any come back this system wont get you out of a fix if you break down on the motorway. An indicator that fits in the end of the handlebar sets you back to the tune of roughly £85. each, AGHhhh, if your engine fails to start and you keep pressing the start button look out for smoke from the melting wiring. The only battery that will turn the engine over is a lithium battery that sits within the given parameters that were given to me regarding seat base height and the restrictions on the depth of the electrical tray. I love solid state electrics as the offending component can be replaced at little expense. I’m not going to go on with electrics and I’m gladly moving onto the solid state stuff such as carbs.

When I build an engine I obviously set the cam shaft timing and statically set up the ignition knowing that when the engine is fitted that it will fire up with no probs except for remedial adjustments to the carbs that have been rebuilt to the book.

It is the day of the start up and all had been primed with lubricant and fresh fuel. Press the starter button after enabling the electrical system with its wand and nothing, not even a pop. Ohhh! What the f**k is going on here? Suspect carbs, even though I have rebuilt them to the book remove carbs and check all of it, ok. Check sparks, ok. Check ignition timing, ok. Getting paranoid and starting to doubt the cam timing, looked at it, ok. Looked deeper into NGK fake plugs. Turning the engine over on the starter produced the off gun shot from the exhaust.

Along time ago we has a similar problem with a CB750 and a CB400 they are both customized to customers specs. In the past I have fitted all sorts of filters including K and N filters to all sorts of engines with minimal tuning to the air/fuel screw. The aforesaid 750 and 400 would not run and showed the exact problems that I was now experiencing with mats CB550. As stated previously that every thing has checked out but due to customising there is very little scope to fir any other filters other than the sponge ones that mat supplied and we fitted. When the CB750 and CB 400 were fitted with there original air boxes they stated on the button, so now I’m wondering if this is one of those finicky engines.

The standard air box has an engine breather from on top of the camshaft cover. This breather circulates hot air and oil particles to the carbs. Honda chose this system to cut air pollution for the USA market particularly California. The oil particles also aid lubrication to the carb slides and then pass with the fuel and air mixture into the combustion chamber. Remember the air box is fitted with an air filter that has an impedance on air flow to a degree. If you remove this system some bikes will suffer and refuse to start. You may think that adding a set of bigger carbs may solve the problem by it does not as we have tried it.

Another item to look at is plug cap resistance and plug resistance, a typical plug that is marked with an “R” in its reference number, IE: DR7ES, denotes that its a resistor plug. If we look at the spark plug cap you may see a number followed with an ohms symbol. It may be marked with the value of 5 ohms or 10 ohms, the value of 5 ohms in fact times by 1000 equalling 5000 ohms. If we choose a plug cap with 5000 ohms resistance and an “NGK” plug marked with an “R” we can expect a combined value of between 9000-10000 ohms “9k-10k” resistance. Now I’m not an electronics expert but I have read much conflicting information tattled about on forums that could be fulfilling or totally misleading but when I put a now resistant plug of the correct value for the CB550, D7ES it gave a good fat spark. The correct value of 5000 ohms caps were retained. Maybe the electronics ignition system doesn’t like loads of resistance, the new plugs after fitting showed a good fat spark and good colour. I rechecked that the spark leads were fitted to the requisite pots. Honda have a firing pattern of 1243 from the left side of the machine when you are seated. Pots 1234 from the left of the bike is not the firing order and I can bet your bottom dollar this is how many confusing starting problems are met. Plugs in, push the starter button and bang, she chimed into life but sounded a little puffy from the exhaust but accelerated freely but not under load. Check the leads and found 1 and 2 had got mixed up “see!”, even I can make this mistake after how many engines I’ve built. Change the leads over “WOW!”, she runs as sweet as a nut.

Things to look out for when not starting is experienced is as follows; dirty carbs, blocked carb jets filters, spark plug grades, and most of all firing order if the numbers are missing off the leads.