Stotfold Engineering’s Aqua Blasting machine. ‘Comet’ wet blasting unit made by Abrasive Developments Limited.

NAMES: Aqua blasting, also known as vapour blasting and wet blasting.

WHAT IS AN AQUA BLASTER?:

Essentially it is a machine that operates using a medium compressed air supply and a high pressure pump. The sump of the cabinet type aqua blaster contains water and a measured amount of media. The water and the media are mixed in the sump. The high pressure pump forces the mixture through a rubber hose to the gun, which is usually manually held via two apertures in the cabinet that have rubber gloves fitted on flanges inside. The whole cabinet is rendered waterproof through the rubber seals to the side door. The door is for loading any work or article into the cabinet. Aqua blasting cabinets normally have a rotating table within the center of the cabinet. This is used to rotate heavy items, such as engine casings or other difficult to maneuver parts. The table is normally rotated manually by the operator.

HOW DO AQUA BLASTERS CLEAN?:

Aqua blasters clean materials as well as surface etch. The cleaning process takes place when water and the media are passed through a nozzle at high velocity. The velocity is important and can be made manually through air intake pressure adjustments. The nozzle, which is made of tungsten, guides the water and media in a controlled stream. When this stream of water and media is directed at the surface of the item to be cleaned. The surface of the item is subjected to an erosive affect.

The point of putting parts through this erosive or scrubbing cycle using aqua blasting is to clean them down to the original base material. For example we were given a ‘Primus’ camping stove that had heat proof paint on it. The camping stove case was made from very thin metal and would not stand up to aggressive treatment, such as shot or sand blasting. The aqua blaster was set to just strip the paint down to the base metal. This is done by controlling the air pressure or adjusting the distance the nozzle is from the work. The paint was stripped and only the bare metal was visible. Now the bare metal had to be subjected to the erosive effect of aqua blasting. This was procured by playing the nozzle and fourth across the item until the desired satin finish was to ones liking and all the paint and rust had been removed.

The erosive or scrubbing affect on the surface of bare metal, when you get through the layers of paint or rust, is non-aggressive, in other words it does not have an adverse effect on the surface structure of the base metal, in fact a beneficial effect.

WHAT EFFECT DOES AQUA BLASTING HAVE ON MATERIALS?:

Take a set of crank cases for example. When they are sand-cast, they were left to weather or age before they were fitted with all internal components, as were the cast iron parts such as the cylinder liners and cylinder heads. The natural aging of these parts was crucial to let them settle down and loose all of the inbuilt stresses created through the casting process. Later modern castings are pressure fed die castings for greater mass production. These have lots of stresses in them and they retain them.

I was given a set of die cast crankcases to experiment on. Firstly I cut through the fly wheel housing with a milling cutter. I then measured the amount of distortion caused by this machining. I then took the same cases and aqua blasted them. I then replicated the previous milling machining on the flywheel casing. The amount of distortion on the aqua blasted case was 75% less than on the non-blasted case. This bares out the advantages of aqua blasting. We have however had not problems with distortion on sand-cast castings, whether aqua blasted or not.

Triumph T140 crankcases aqua blasted

Aqua blasting not only cleans down to the base structure, but also normalises it. The scrubbing action of aqua blasting on the base metal is found to have no adverse affects on material stability, whether it is in thick or thin sections.

When we propel a media alone, such as shot or sand-blasting without having water involved, the media hits the object at a force of its given velocity. When the impact of the media takes place on that object it will have an adverse or restructuring effect on the material it bears on. The application of water into the mixture gives a cushioning effect to the blasting process, allowing all impurities on the surface to be removed without damaging the structure of the material.

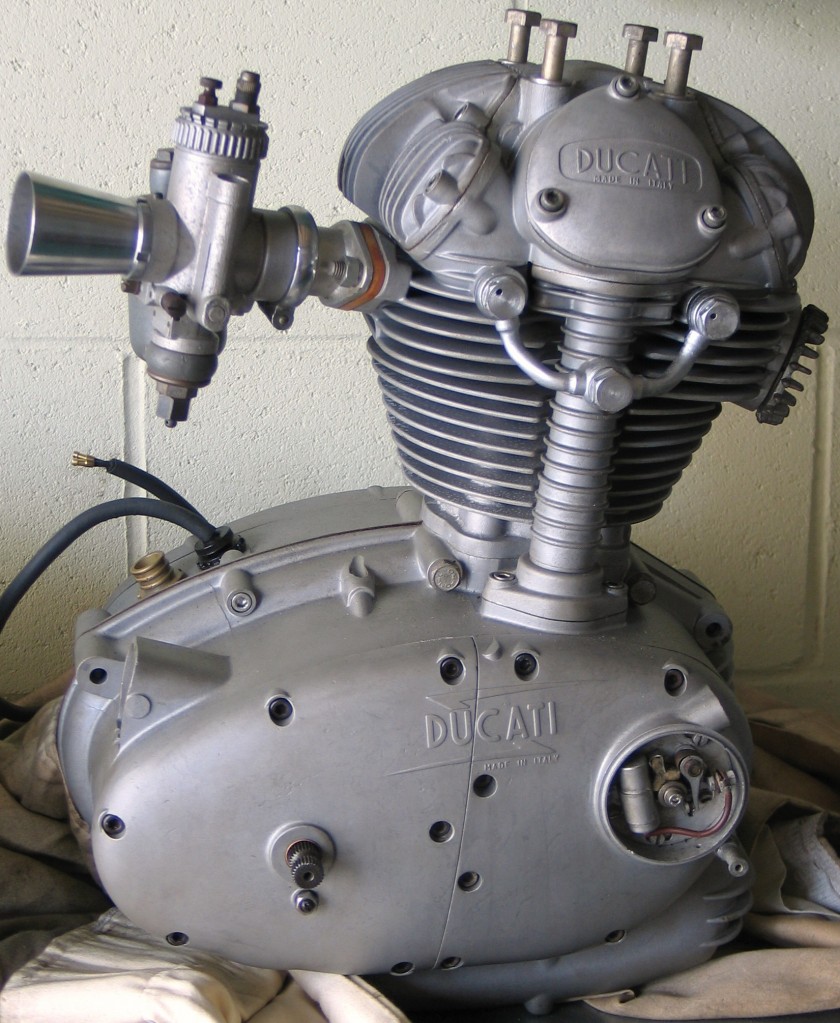

A Ducati Mach 1 engine being restored here at the workshop. All the main engine parts were aqua blasted before assembly.

WHAT MEDIA PRODUCTS DOES AQUA BLASTING USE?:

Almost anything can be used in conjunction with water to produce a clean satin finish. Varying the media has only a slight affect on the final product finish. Media’s include; glass (150-200 micron), calcium carbonate, olivine, almandite, garnet, and aluminum oxide. All these produce a nice satin finish that is sought after by the classic motorcycle and car fraternity.

WHAT CAN AQUA BLASTING CLEAN?:

Aqua blasting struggles on some paints, most of all powder coating and also some of the casing paints found on Japanese motorcycle engines. We usually use a stripper, such as ‘Nitromors’, to remove and soften the coating before finishing with aqua blasting. Sometimes this require several re-applications to fully clean the object and it can be quite time consuming. Aqua blasting cleans the gummy lacquers from carborettors and most paints from steel and aluminium surfaces. Oil stains on engine cases and con-rods can also be removed.

WHAT SHOULD YOU NOT AQUA BLAST?:

There is no discernible change in diameter or bore on objects after aqua blasting, however surfaces that require running fits and tight clearances should not be touched with any type of blasting equipment. They should be masked off with tape or covered. The following should not be aqua blasted:

- Big end bearings : although needle roller cages can be blasted.

- Pistons : the reason being it upsets the diameter patterns of the circumferential grooves that pick up oil to lubricate the piston skirt.

- Small end gudgeon pins

- Any white metal or lead bronze materials that have a bearing surface

- Valves: unless the stems have been masked of.

WHAT ARE THE MAIN USES OF AQUA BLASTING?:

Aqua blasting is used mainly in the restoration, renovation, and preparation of metals and some other materials. Aqua blasting has also become favourable for graffiti removal.

At Stotfold Engineering we cater for classic and vintage motorcycle and car clubs. Work includes engine and gearbox casings, crankcases, engine covers, barrels, carburettors, frames and swinging arms and many other vehicle components. Any stripped down basic component can aqua blasted by us. We can aqua blast steel, brass, titanium, aluminium and cast iron. If we repair aluminium or cast iron for you we can then finish the item off with aqua blasting to hide any signs of repair.

WHY IS AQUA BLASTING MORE ADVANTAGEOUS THAN SHOT-BLASTING?:

Firstly shot-blasting is a destructive process. It erodes metal surfaces, leaving them open to further corrosion, unless immediately painted with a phosphate type paint. Shot-blasting produces dust, heat and releases toxic bi-products into the atmosphere. It also wears out hoses and nozzles at a greater rate and so this cost has to be passed on to the customer. Because aqua blasting uses a aqueous media it does not produce dust or heat. Heat produces rust on bare metal surfaces. With aqua blasting there are not toxic or chemical compounds to attack the atmosphere or earth as the bi-products are filtered out by a special water trap. Aqua blasters run for hours on a single fill of media; grit, bead or glass etc… The aqua blasting nozzles and hoses last thousands of hours longer than the equivalent shot-blasting fittings.

WHY IS AQUA BLASTING MORE COST EFFECTIVE?:

As previously explained there is less waste, less wear on parts and no toxic wastes. All of these factors have a positive impact on the customers costs.

HOW SHOULD THE PARTS BE CLEANED AFTER BLASTING?:

It is imperative that all parts are meticulously cleaned after using any grit based cleaning. After general rinsing and washing grit can still be lodged in small orifices like carburettor jets, oil ways and any other small cavities and voids. Stotfold Engineering, after aqua blasting, completely removes every particle of grit from parts by washing in paraffin and then ultrasonically cleaning them. Sound expensive, but you should take into account that an engine can expire very quickly from a few particles of grit. Here we also recommend that any new build engine should be started and run, on any cheap mineral oil of the correct grade, brought up to working temperature and then have the oil and filter changed. This allows the engine to be fully flushed of any possible grit contamination.

By Terry Ives

I like your style, the fact that your site is a little bit different makes it so interesting, I get fed up of seeing same-old-same-old all of the time. I’ve just stumbled this page for you 😀

More power to you.i have actually bookmarked it to show some of my friends. By the way, after paying 40 dollars for Motorbike Manuals on Ebay, I have uploaded or linked to 4000 manuals at my website that you can download for Free. http://freemotorcyclemanuals.net

I think that is an interesting point, it made me think a bit. Thanks for sparking my thinking cap. Sometimes I get so much in a rut that I just feel like a record.

I really liked reading your post!. Quallity content. With such a valuable blog i believe you deserve to be ranking even higher in the search engines :). Check out the link in my name. That links to a tool that really helped me rank high in google. This way even more people can enjoy your posts and nothing beats a big audiance 😉

I’m so glad to have found your web page. My pal mentioned it to me before, yet never got around to checking it out until now. I must express, I’m floored. I really enjoyed reading through your posts and will absolutely be back to get more.

oh cool, this information is really useful and definately is comment worthy! hehe. I’ll see if I can try to use some of this information for my own blog. Thanks!

Great post! I have bookmarked your site – do you have an rss feed I can subscribe to?

Major thankies for the article post.Really thank you! Keep writing.

Good journey and experience!

I just sent this post to a bunch of my friends as I agree with most of what you’re saying here and the way you’ve presented it is awesome.

You certainly deserve a round of applause for your post and more specifically, your blog in general. Very high quality material

Howdy there,this is Laurene Rubidoux,just observed your web-site on google and i must say this blog is great.may I quote some of the information found in the blog to my local people?i’m not sure and what you think?in any case,Thank you!

It’s motivating to see that the beginner bloggers are once again aiming at providing a more rounded content rather than just aiming on rubbish and garbagy articles. In this way the assets of individual article are more likely to be discovered.

I really like and appreciate your blog post. Keep writing.

Tremendous post you’ve scored here! The internet is overflowing of horrid writing and I was grabbed by your limpidity. Your closings are exact and I will straightaway subscribe for your rss feed to remain up to date with your up future day postings. Yes! I admit it, your authorship style is special and I am going to operate harder on mine.

It’s so refreshing to find articles like the ones you post on your site. Very informative reading. I will keep you bookmarked. Thanks! .

Great post. I was checking constantly this blog and I’m impressed! Very useful information specifically the last part 🙂 I care for such information a lot. I was seeking this particular info for a very long time. Thank you and best of luck.

Great article,I specialise in pre 1980 Mercedes Benz and I pay someone a huge amount of money to get parts wet blasted using a similar machine to yours. i have bookmarked your page so my customers can see how we such a nice finish on the alloy parts. We have been looking at doing the inside of hydrualic suspension struts to restore the satin finish and this looks like the way to go.

it’s a very impressive idea which gives a fantastic finish.

I hope you never ever cease! This can be among the best weblogs You will find ever study. Youve got a few mad talent right here, guy. I merely desire that you simply dont drop your thing because you happen to be definitely one of the coolest blog writers around. Remember to continue the good work as the net requirements you getting the news out.

I’ve been absent for some time, but now I remember why I used to love this website. Thank you, I’ll try and check back more frequently. How frequently you update your website?

every week or so

Pretty part of content. I just stumbled upon your

web site and in accession capital to assert

that I get in fact enjoyed account your weblog posts.

Any way I’ll be subscribing for your augment and even I success you get right of entry to constantly quickly.

Pingback: penis traction

Your article has proven useful to me. It’s very informative and you are obviously very knowledgeable in this area. You have opened my eyes to varying views on this topic with interesting and solid content.

Pingback: carry underwoods

Pingback: JOk jok