Good heat resistant engine paints are getting difficult to source as some have stopped being produced due to regulations on there chemical make up and possible health hazards. For the home based motorcycle restorers, the preferred method of applying paint is by spray in the form of rattle can. Very good heat resistant paint used to be available in tins for brush coating. The market appears to have dried up for these.

What the engine restorer is looking for in a paint is primarily heat resistance and secondly, resistance to petrochemical attack. In my opinion one should look at it the other way around. I think the thing that looks bad on an engine is not the baking of paint into engine and barrel castings, but the tainting of its finish by chemical reactions from petrol, hot oil, brake fluid or even general handling of the finished product.

Most paint contain some household acrylic based ozone friendly spray paints bare up to considerable heat and reheating but are not tolerant to a good petrol soaking when cold or even a splatter of WD40. I have tested Plasticote acrylic paint in an oven on regular gas mark 9 for 4 hours and have not seen any burning or ash, but the finished product was poorly resistant to petrol and chipping. I have read on many forums concerning heat resistant or heatproof paints. Almost all paints, automotive, are tolerant to excesses of heat unless you paint your exhaust pipes in enamel paint or Dulux brilliant white. A heat proof painted or sprayed finish can be attained by any heat proof paint in Halfords or any other motor factors suppliers. However many of these are very liable to be attacked by petrochemical contact. Sadly, through reading in a few forums that Tecote was the equivalent replacement for PJ1 I purchased 10 cans of the stuff and proceeded in using it on a customers Honda crankcases and barrels. As opposed to PJ1, I found the intensity of blackness to be poor, it was moor or less, when dry to be a very deep roasted coffee brown, its petrol and WD40 resistance when baked into the casting was very poor and it stained easily when it come into contact with the aforesaid mentioned. The staining was in the form of a circular ring in the paint, is petrol was dripped onto its surface. The was due to the petrol drip weakening and dissolving the surface directly and immediately on contact, the resultant effect was dissolved soft paint being forced away from the point of impact and creating a ring stain. Hammerite Stone Chip, even though not advertised as heat resistant showed the same characteristics. Some paint such as Simoniz silver were affected in a different manner, on petrol contact they would partially soften but not stain. If the Simoniz silver surface was left to dry it would revert back to its natural characteristics when the engine is run and the paint is reheated.

If we were to spray a barrel with Hammerite satin as many forums condone as a good engine paint substitute for PJ1. We would find it tolerant to WD40 petrol, but it would soften when initially heated and would not be resistant to petrochemical attacks until it cooled down. On reheat it would fair better but would still be partially harder that the previous heating. Hammerite satin seems to get tougher and more resistant as it goes through many heat transitions. I thought I would give a brush on black paint a look in. on testing it, I found its intensity in blackness very poor compared to, lets say Tecote witch I considered “F” for fair. Its resistance to petrochemical attack “F” to “P” poor. I would use this paint for 2 stroke exhaust systems where beauty is of not so much value as no brough superior barrels or Vincent crankcases.

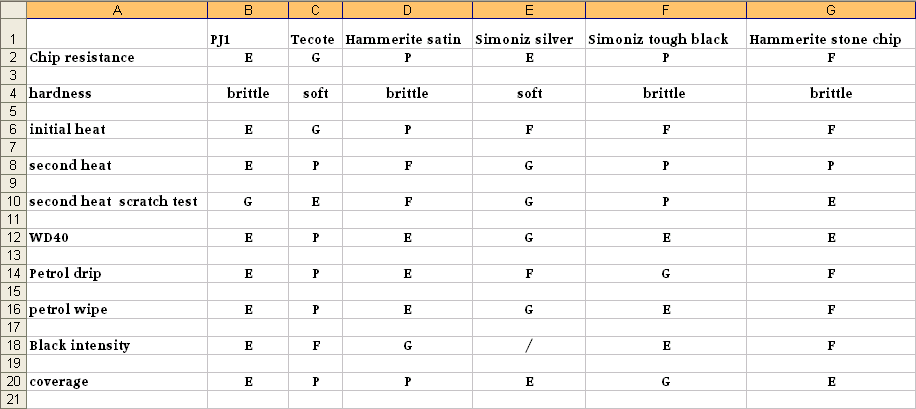

I am now going to set out a graph of what I have discovered, the graph consists of some paints that I have seen mentioned in many forum websites on the web. The paint that I have chosen to feature in the tests are in no chronological order or order of superiority they are randomly picked from the most mentioned paints in forums. The tests were rigorously carried out, employing a polished plate of aluminium, 1.5mm thick. There were no primers used to key the paint to the polished base metal, so all paint finishes had exactly the same treatment. After a month of curing on it’s base metal. Paints will show an appreciable percentage value in adherence to the base material if it has been aqua or shot blasted but its basic characteristics against other out performing paints will not change. All paint’s went through 2 hours of initial heat on gas regulo 9 and second heat of 2 hours of the aforesaid heat.

The chip resistance test was carried out using a stylus with a 2mm point that was dropped on by a ½ oz weight at 300mm height. The hardness test was carried out manually with a very sharp stylus held by a mechanism and drawn over the paint samples by hand. The chip resistance and the hardness have close correlations.

The scratch test was carried out exactly as in the hardness test, but this was done after the second heating session. The WD40 test was one small drop of WD40 left for 30 seconds and wiped away with tissue, this was done after second heating. Petrol drip, as above but left to settle and dissipate in its own way. Petrol wipe, one drip of petrol left on painted surface after second heating for 30 seconds and then manually wiped away. Black intensity was visually measured. If 3 good coats of paint are sprayed or brush painted and it is appeasing to the eye and one has a superior product to base the intensity of blackness on. The coverage is based on one cote of paint or spray according to manufacturers recommendations. The best were Pj1 and Hammerite stone chip and this is what I based the order of e”excellent ,g”good”,f”fair”,p”poor”.