The CB 900 like all of the old CB range is like pulling a sandwich apart or if your given 2 engines to build one good one its like making a sandwich. Everything is made up of layers. The CB900 is an easy engine to work on because of these features. Gear clusters can be seen how they work together to select gears while laying in the bottom part of the crankcase. As one builds on one of these engines it will be notices that it is built in modules, IE the oil pump is a separate part within an aluminium casing and the cylinder head is a work of art with its 16 valves and double camshafts.

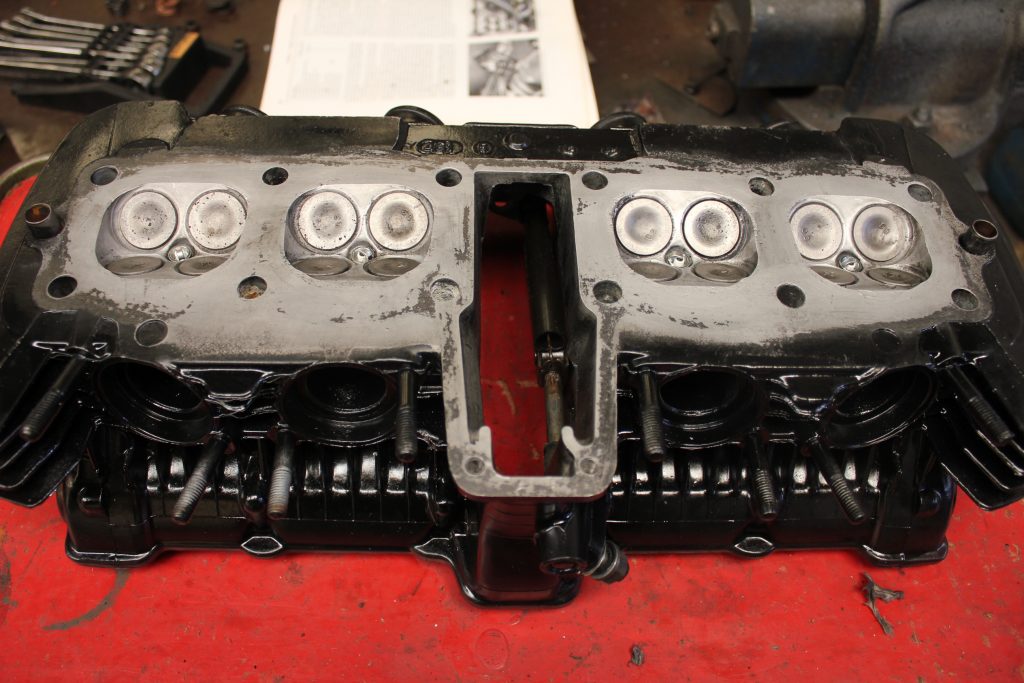

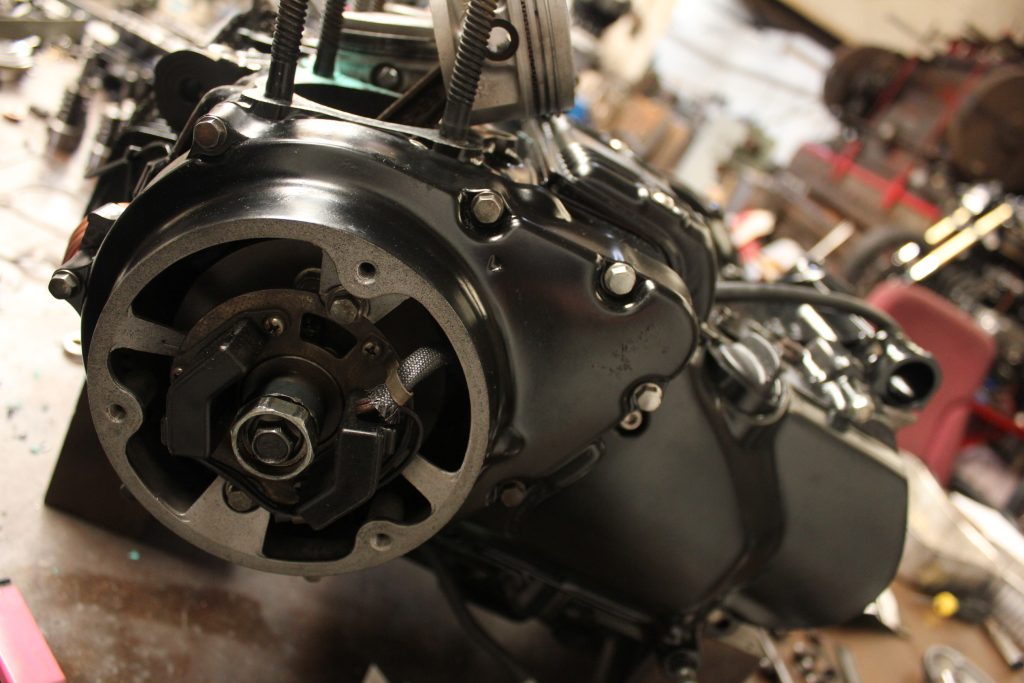

The Japanese motorcycle industry really got it sorted when they found that camshafts would quite happily run in plain aluminium. If the British had designed it they would have used a multitude of white metal shells. The bottom end like all CB’s is literally unbreakable as all the gears are so generously thick as are all of the shafts. The only week points on the CB900 engine is the gear selector on it but you would have to give it some brutal hardship to damage it. Another weak point is if you do not adhere to torque settings as threads in casings can easily be damaged. Crankshaft bearings often suffer from surface erosion particularly if the engine has been stored somewhere damp without or with old engine oil in it. The commutator on the right hand side of the engine can also suffer from damp conditions and will need cleaning.

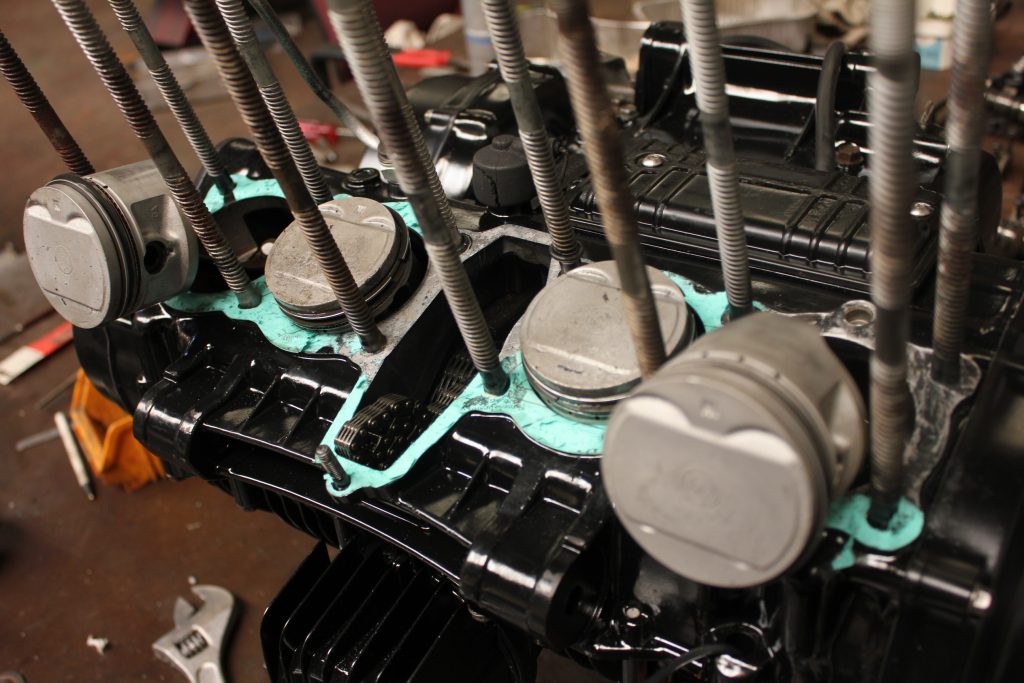

The engine that I rebuilt for a customer had to be made up from the best parts of 2 engines. Both engines were in excellent condition except for piston rings and mains bearings. I stripped both engines down and got out the micrometer and other measuring instruments find all the best parts. Some were like new and some were showing a tiny bit of wear. All the best parts were selected for the rebuild in the customers chosen crank case. Parts from one engine will be happily interchanged as all parts have been machined to such exacting dimensions, if you rebuild a CB Honda do not skimp on this as you will end up with a leaky bike.

The head gasket and barrel bottom gasket are expensive at about £80. I got the engine together with new top and bottom gasket and each valve reshimmed to Haynes manual spec when the customer insisted on pictures of the rebuild so all pictures in this blog were taken after. Boy what a piss off when they do this as it is not normal company protocol to do this as a report. On breakdown of what has been done to the engine is the norm. Our trade is engineering, not photography, maybe I should charge a rate for the rebuild and a rate for the engine pictures. I duly took all the top end off of the engine and destroyed the gasket amounting to £85. The customer must have had some bad experience regarding engine work or a shitty deal with a best friend. He also insisted that I give a warranty and that I was not to use any old gaskets as he would be even more furious that he already is as there were no photos.

Reshimming the valves is no big problem but it takes time. There was a box of shims that came from both engines as the customer had dismantled the head. The inlet valves are set with closer clearances so I took all of the thinnest shims out of the box and fitted them to the inlets and got out the feeler gauges to measure the clearances, some shims had to be swapped around to make up the right clearances , as the valve clearances are quite open and not tied down to 100ths of a millimeter it is not so big of a task to get what is needed . In a lot of engines valve clearances are attained by adjusting a screw and locking it in position with a lock not. On the CB 900 Honda it is fitted with bucket type valves. If you imagine a valve that wants pushing open by the cam on the camshaft. Think of a valve with a precision hole cut above its stem and a bucket with straight sides on its outside diameter that runs up and down inside the precision hole above the valve stem and pushed the valve stem to open the valve when it is actuated by the cam on the camshaft.

Disturbing a rebuild is very annoying as the strip down and rebuild is wasted time and money and not a joy at all. I condone using a Haynes manual for CB rebuilds as there are loads of pictures. I find Clymer manuals very irritating as they are packed with too much script that can cause one to focus away from the donkey work.

What isn’t irritating is the removal of the cylinder head as it does not upset the valve clearances neither does the gasket change to barrel and head, there are no silly push rods. If you grind the valves into there seats it will be a different matter as it will mean you will have to do lots of measuring and reshimming. Here is a picture of the spare set of cases that we accidentely painted at no cost to the owner

The paint we use is quite toxic and a high level of ventilation and filtration is needed in a spray booth. The paint is not very petrol proof until the engine is fitted and run up to temperature, then it becomes excellent. Unlike the expensive BJ1 fast black that does not need heat to make it petrol proof. Good paint costs a lot but ours is half the price of PJ1 fast black and that keeps our customers happy.

20th June 2018 note.

We received a message from the customer with a picture “below”.

“I see you have a blog about my engine, the CB 900 F2C. The bike is now finished, running very nicely. One or two little issues, but nothing I couldn’t fix.”

CB 900 F2C

Here are some unrelated Honda CB’s that I restored and would like to share with you, pictures below.

Thanks for reading.